You are here:

Introducing and Learning More About Team Green: The Versatility of Team Green According to Technical Specialist Russ Watts “Today’s hardwood floor job sites are more demanding than ever before, and that means you must be

Introducing and learning more about Team Green: The Precision of Team Green According to Sales Specialist Michelle Stavich “Today’s world is so fast moving- everyone wants things immediately, right here and right now! This is

Introducing and Learning More About Team Green: The Durability of Team Green According to Operations Manager Schawn Lawson “In our industry, durability is 100% key- without it, you don’t have anything. With how we use

Introducing and Learning More About Team Green: The Tradition of Team Green According to Vice President Marc Schulz “In today’s world, business is a lot about faster production, quicker turnover and obsolescent products. There are

We take versatility to the next level- not just with our equipment, but also with our team. We are proud to wear multiple hats and cross train our entire staff on all aspects of the

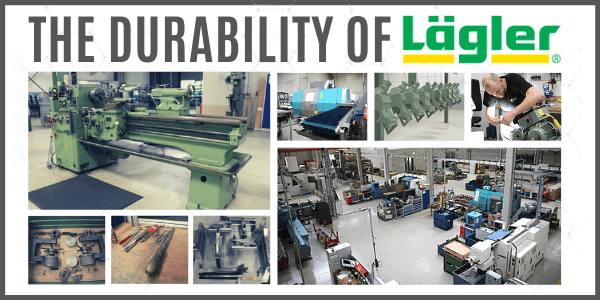

Whether we are using hand tools, milling and turning equipment from the 60s, or state of the art CNC equipment, for us it is all about precision. Our tolerances are measured in microns. As a

Durability and quality have been the foundation of our success since we started in 1956. We take enormous pride in the longevity of the machines we produce. Our equipment is intended to last decade after

Tradition: It’s In Our DNA LÄGLER, the mechanical engineering company, is known worldwide as the market leader for floor sanding machines. The famous HUMMEL® belt sander is just one milestone in the company’s 64-year history,

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.