You are here:

Besides getting awesome Instagram shots on the job, of course, getting the floor flat is the most important part of sanding wood floors. But that’s harder to get just right if you don’t take a

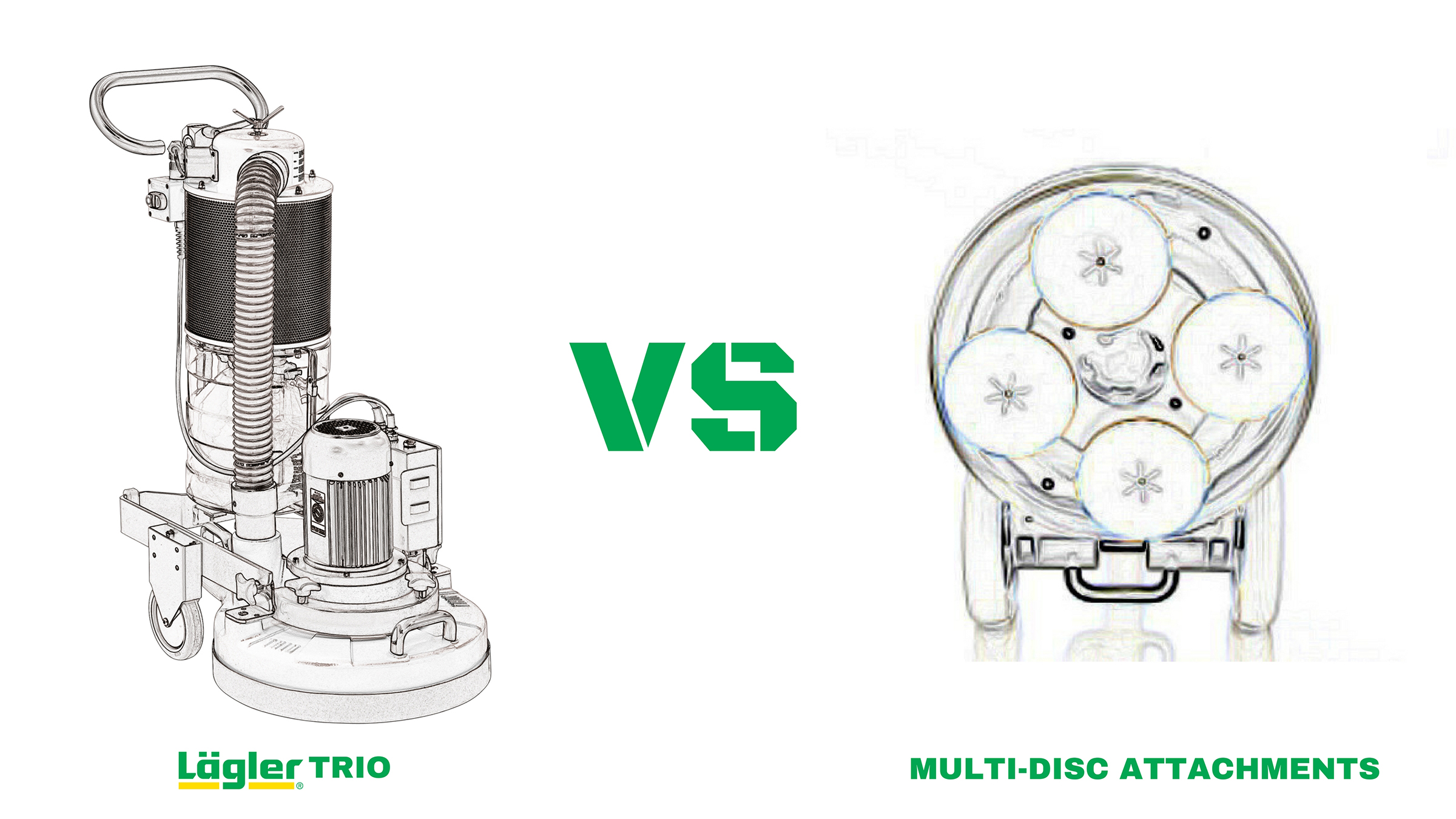

Lägler engineers took on a special “Coke vs. Pepsi” kind of project in 2015. They spent more than eight months testing to see if the TRIO really held its own against competitors’ multi-disc attachments, and

We’re doing what people do at the end of one year, beginning of another. We look back at what we did well and what we can improve. We always want to keep doing better. That

We recently wrapped up our second Lägler Fly and Sand trip of 2016. It was a new step for us and Lägler GmbH, in nearly 10 years of offering this lottery, to put together two

Editor’s Note: Brandon Santiago, of Cleveland Hardwood Restoration, was one of 10 wood flooring professionals whose names were drawn as winners of this year’s annual Lägler Fly and Sand lottery. Below, is Brandon’s take on

Lägler’s certification program – Premium Sanding Technology (PST®) – is about two things: our relationships with contractors, and their success with sanding and finishing wood flooring. Many sanding professionals across the world know Lägler machines,

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.