You are here:

The last thing you want with a floor you’ve sanded and finished is to have sanding marks pop like neon signs in the night. If you can spot sanding marks while standing at full height

Those who don’t know call the Lägler TRIO a buffer. Only those who don’t know. The way to feel what’s what is to get your hands on the TRIO and do some work – and

A lot of floor sanding pros probably are confident in their “how to sand with a big machine” knowledge. Many of you should be. Yet here we are talking about it, so hang with us

Besides getting awesome Instagram shots on the job, of course, getting the floor flat is the most important part of sanding wood floors. But that’s harder to get just right if you don’t take a

Sanding wood floors is a science. Knowing that science is what sets you apart from DIY homeowners who want to save a buck and try their luck. In fact, when a lifestyle blogger reached out

There are two approaches to floor sanding: guesswork and science. Guesswork creates variables and challenges in sanding jobs that aren’t there. It causes the professional to change his or her approach from job to job,

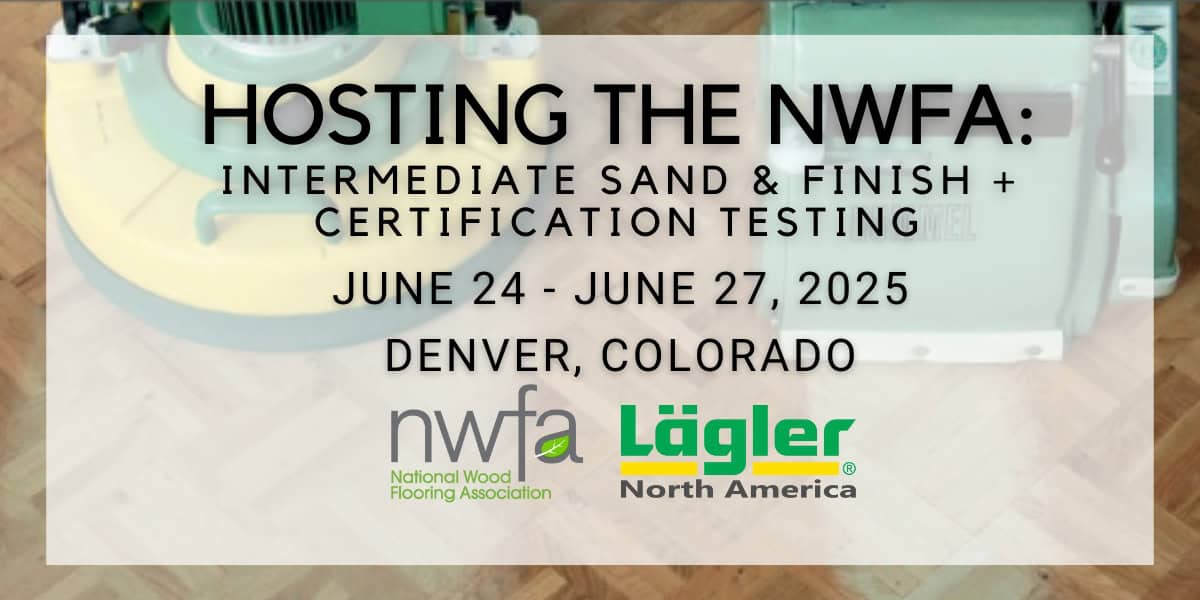

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.