You are here:

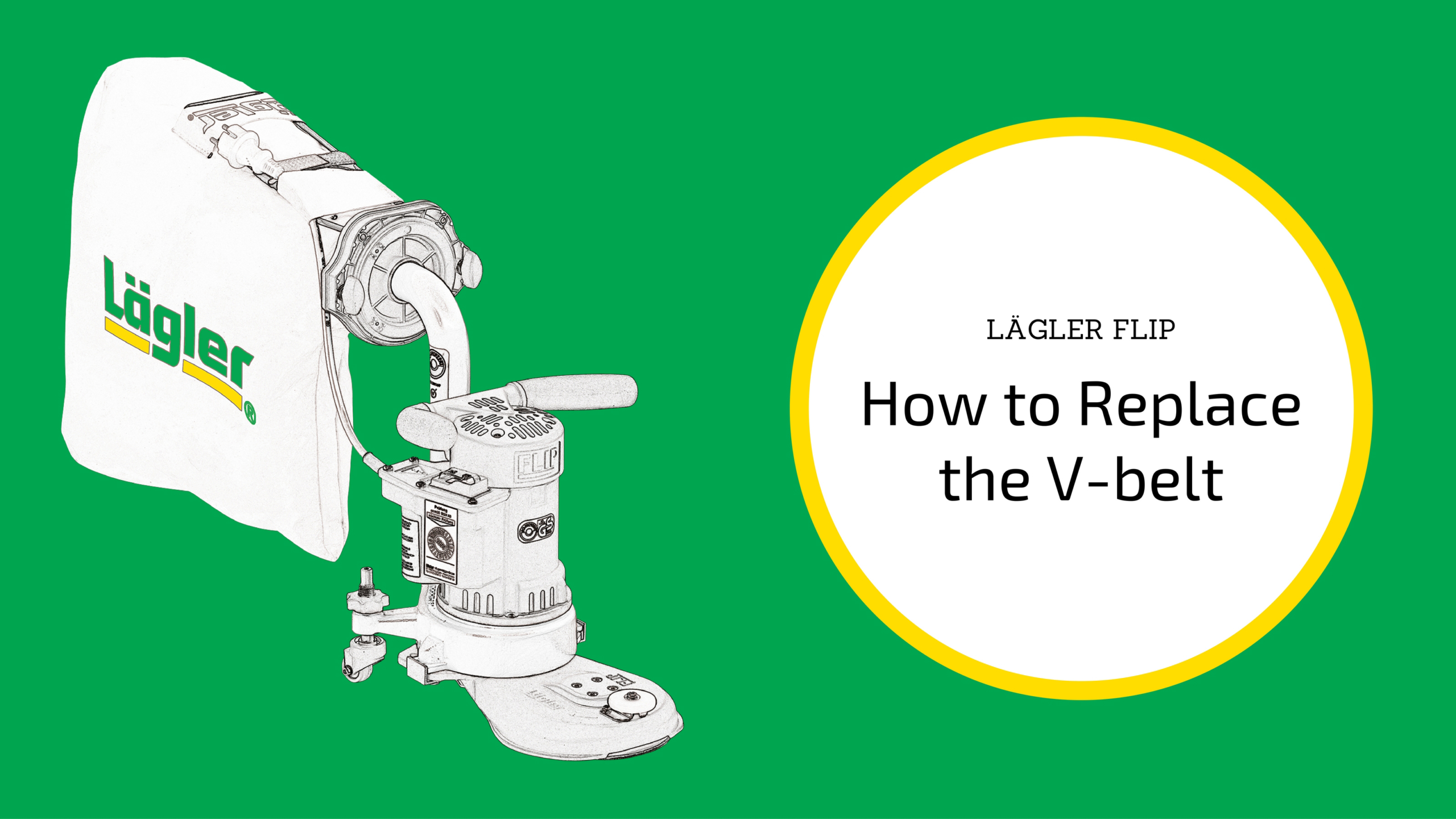

Have you noticed your Lägler FLIP® acting a bit different lately? Maybe you’re having a tough time starting it or the working speed has decreased. Maybe it feels like it isn’t running as smoothly as

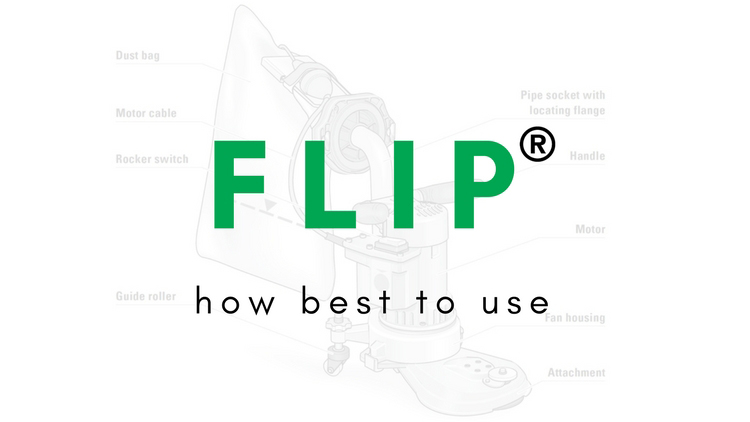

It seems to be something like an open secret that the Lägler FLIP® is engineered for versatility. The information is out there, in Lägler’s “Sanding of Wooden Floors” manual and in some pieces already on

We’re doing what people do at the end of one year, beginning of another. We look back at what we did well and what we can improve. We always want to keep doing better. That

Flexibility of tools on the job stands out. And the Lägler FLIP, with its corner attachment, can be one of the difference-makers on the job site. If you use a FLIP, you know the short

Adjust the Lägler FLIP Wheel Settings to Change Aggressiveness Did you know you can adjust the aggressiveness of the Lägler FLIP? It’s not about the pressure you apply. It doesn’t take any more effort on

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.