You are here:

Those who don’t know call the Lägler TRIO a buffer. Only those who don’t know. The way to feel what’s what is to get your hands on the TRIO and do some work – and

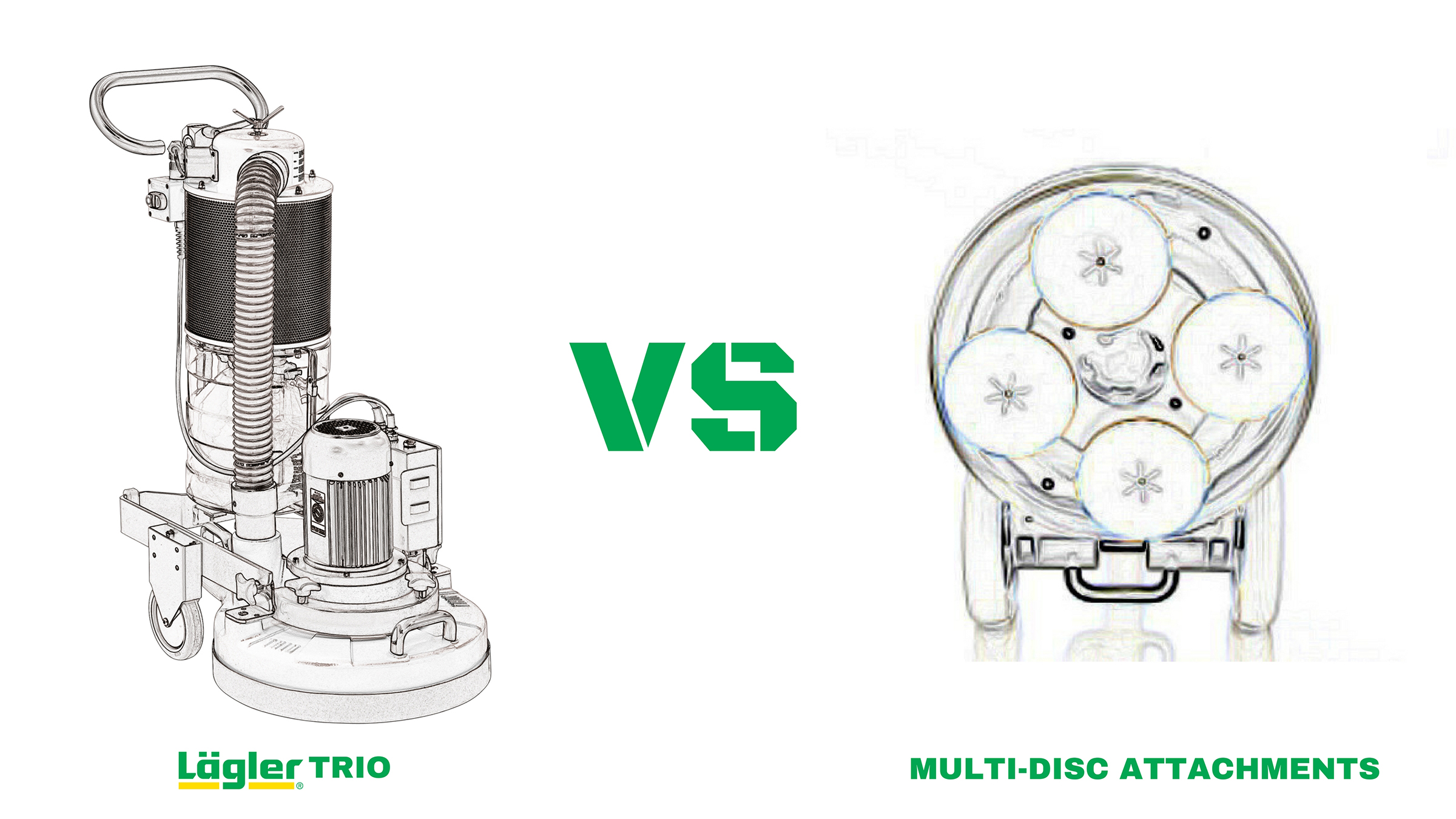

Lägler engineers took on a special “Coke vs. Pepsi” kind of project in 2015. They spent more than eight months testing to see if the TRIO really held its own against competitors’ multi-disc attachments, and

How to Mount the Lägler TRIO V-Belt In our previous blog post, we gave step-by-step instructions for removing the Lägler TRIO V-belt. Here are the steps for putting a new V-belt on the TRIO. First,

How to Remove the Lägler TRIO V-Belt Our how-to blog posts like this one are all about helping you to solve your maintenance questions, especially when you’ve got a tight schedule and need to keep

We’re doing what people do at the end of one year, beginning of another. We look back at what we did well and what we can improve. We always want to keep doing better. That

Good condition of the tooth belt, or the belt that turns the three sanding plates (discs) of the Lägler TRIO fine sanding machine, is critical. No belt, no sanding. It’s that simple. In this post,

Have you noticed the six arrows on the bottom of a Lägler TRIO sanding disc? We point them out during our Premium Sanding Technology training (PST® certification). A lot of times, the guys hadn’t noticed

It’s easy to dismantle and reassemble the Lägler TRIO filter unit. You know it’s time to do this if: You are needing to clean the filter more often than each time you change dust bags

Have you seen our tag #MaintenanceMatters? We use it on Instagram, Facebook and Twitter. Because it’s true, maintenance matters to your machines and your business’ success. Plus, we like to talk about the matters of

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.