You are here:

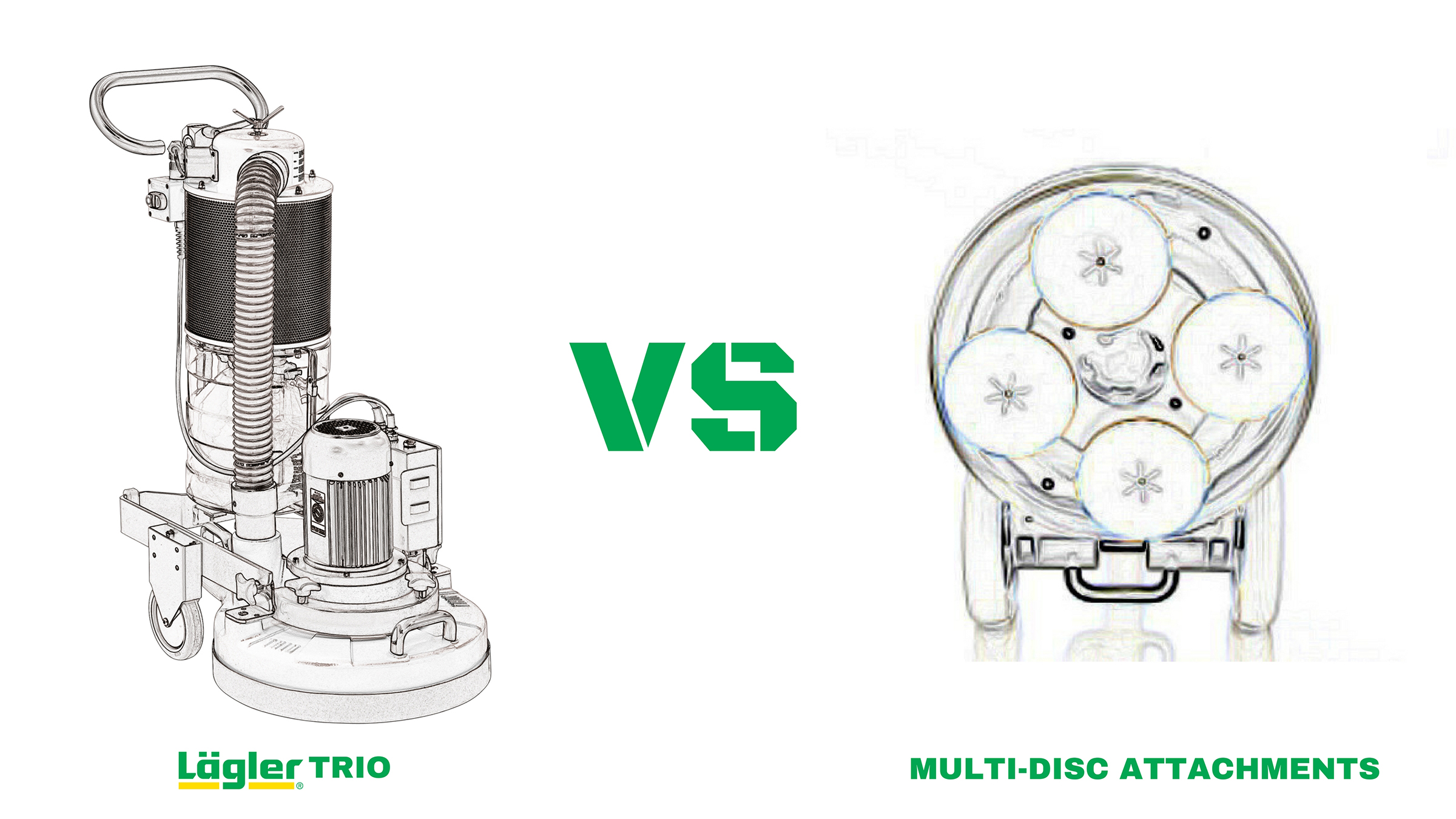

Lägler engineers took on a special “Coke vs. Pepsi” kind of project in 2015. They spent more than eight months testing to see if the TRIO really held its

own against competitors’ multi-disc attachments, and then analyzing their test results.

After all, it’s useless to hide from truth and blindly follow bias for the company, especially if there’s no substance to it. You’d know the difference

just like we would.

Obviously, the engineers had expected their designs – and massive investment in the machine since it was invented and put out on the market in 1993 – to

be everything they’d planned. But since the TRIO entered the market as a one-of-a-kind fine sanding machine, competitors have come out with their own

ideas to counter the TRIO, all options that are more affordable to make and for contractors to buy.

Affordable is good. Lägler’s take is that investing in quality is better – and more affordable in the long run.

Competition is good, too. It pushes our games higher, right?

So, Lägler’s engineers setup their lab experiment to learn for themselves the truth about the TRIO and its competition. They used Lägler’s training facilities

and put each of the machines through the same precise test, using Lägler’s Premium Sanding Technology (PST®) hands-on certification process.

Lägler GmbH factory and PST training facilities in Germany

Why Conduct Multi-Disc Sanding Test?

The trend in wood flooring in recent years has been to achieve a natural surface appearance. Also, the demand for ever-higher surface quality is in

part due to design trends that open up living spaces, use larger windows and improve overall lighting.

People are seeing their wood floors, and appreciating them in ways they often didn’t before. They are choosing to have wood floors as a key

design element in their homes with expectations their floors are something to be showed off.

The TRIO was designed for this fine sanding need.

Single-disc machines are not designed or intended for fine sanding, not even Lägler’s SINGLE.

To achieve perfect surface quality a significantly longer amount of time is required, if using a single-disc sander. Due to the large sanding disc,

the pressure and abrasion are much less.

Manufacturers of single-disc machines recognized these problems. Several of them started offering multi-disc plates as an optional attachment.

Comparison of Multi-Disc Concepts

Lägler set up a real-world job site to test the differences between its TRIO, a dedicated multi-disc sander, and two single-disc machines converted

for multi-disc sanding with attachments. Each was made by a different manufacturer. The engineers compared the three machines using Lägler’s PST® method on a 108-square-foot floor (10 m²) at Lägler.

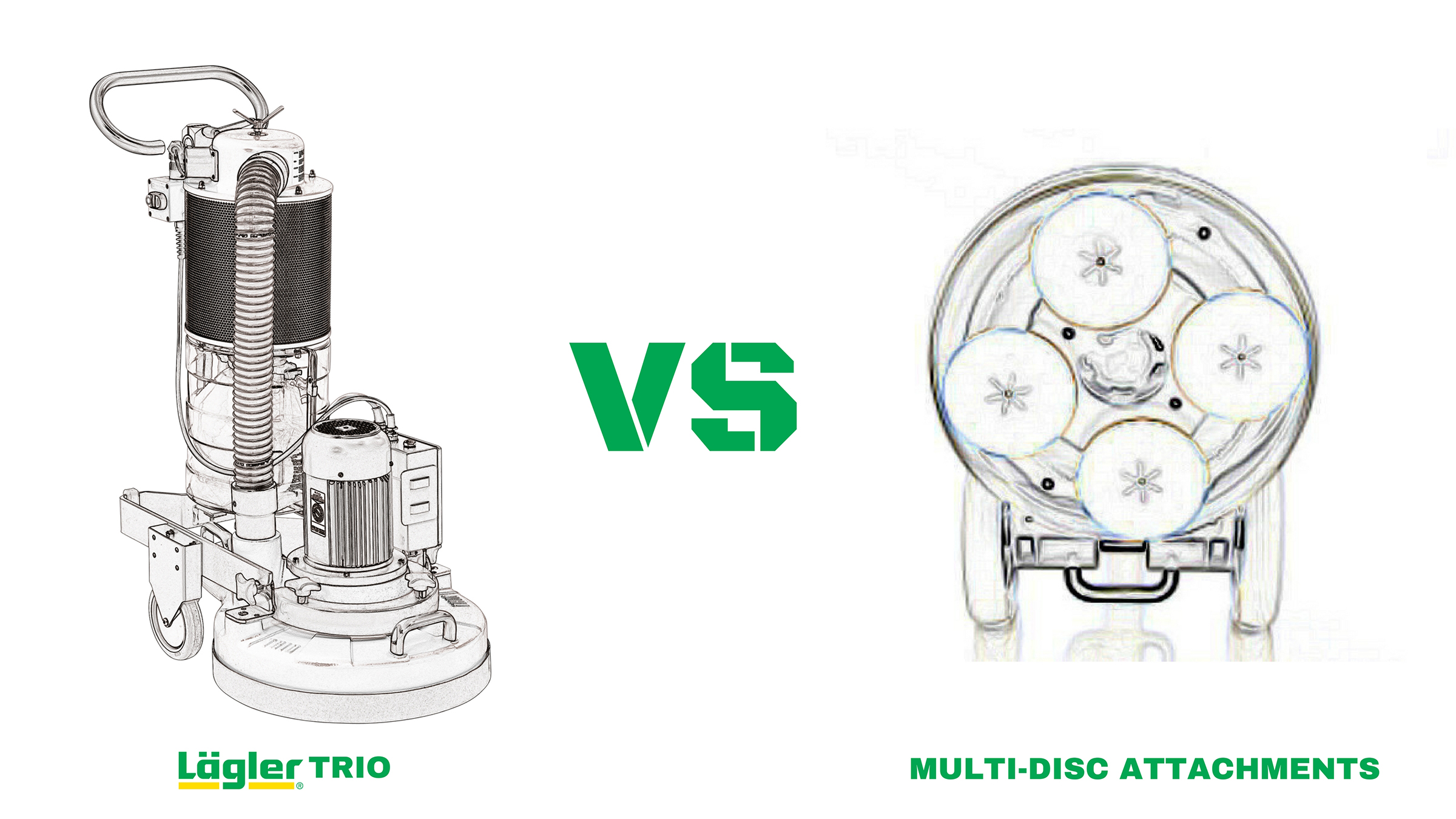

The two single-disc machines in this test (Machines A + B) were equipped with four-disc attachments, in which the individual inflexible mounted sanding

discs were driven by an outer gear ring. The time required for each sanding step was recorded.

The individual times in the image below show Machines A and B needed more time than the TRIO, especially when fine sanding. With Machine A, in particular,

time added up, in part, because it was necessary to sand some areas twice to remove visible scratches from the first attempt.

The key difference-maker – and, frankly, part of the reason why the TRIO was designed the way it was nearly 25 years ago – is the TRIO’s independently

flexible sanding plates. Each of the TRIO’s three discs adjusts to the floor independently, maintaining contact with the surface and sanding uneven

spots to be flat.

The inflexible suspended discs of the four-disc sanding attachments did not adjust themselves to the floor, allowing for uneven surfaces to either

remain uneven or call for additional cuts.

Overall, looking at the chart above, the TRIO achieves a time savings of approximately 25 percent compared to Machine A and about 18 percent compared

to Machine B. The TRIO also produced the flattest floor, due to its flexibility.

Measuring + Comparing Abrasion

To determine the amount of material removed, the wood dust from each sanding machine was weighed after each sanding step. The area used for this test

was 388 square feet (36 m²) of oak mosaic flooring at Lägler.

For the TRIO, the plastic dust bag was removed from the machine’s integrated dust containment cylinder and weighed. For the multi-disc machines, separate

containment systems were needed and the dust was removed from the vacuum bags to be weighed.

The chart below shows the size of abrasives for each machine, the types of machines and disc suspension, and the wattage for each. The image also compares

the machines’ levels of success across the wide range of grits: 40-60-80-100-120. The results of how much material was removed from the floor highlights

the sanding pressure and capabilities of each machine.

Comparing Abrasives

When comparing the success of sanding, testing the sanding machines is only one part. The machine is important for the surface finish, while the abrasive

material determines the actual removal rate.

To compare Lägler’s zirconium-based abrasives against another manufacturer’s zircon-mix abrasives, the Lägler engineers took the TRIO out of this part

of the test. Only the two converted single-disc machines were used. The test area again was 388 square feet (36 m²) of oak mosaic flooring.

The abrasives with the higher zirconium content removed up to 20 percent more material than the zircon mix, depending on the grit and machine used.

Truth in Testing

The truth is what it is. Luckily, for Lägler, no bias is needed to appreciate that truth. Sure, had the results not come out so favorable for the TRIO,

talking publicly about it wouldn’t be the point just yet. Instead, the focus would have been on improving the machine to make sure it gives sand-and-finish

pros the long-lasting quality they need.

The real point for Lägler, as always, is to produce the best quality floor sanding machines on the planet.

Learn More, Earn More

Learn more about the Lägler TRIO and get hands-on experience

in PST certification training.

Plan for one day of PST in Denver (or the U.K. or Germany), and take an extra day for yourself to go skiing, fishing, brewery hopping, or whatever.

Read up – “What Is Lägler PST?”

– and book your class.

Other ways to keep up are: