You are here:

Adjust the Lägler FLIP Wheel Settings to Change Aggressiveness

Did you know you can adjust the aggressiveness of the Lägler FLIP?

It’s not about the pressure you apply. It doesn’t take any more effort on your part.

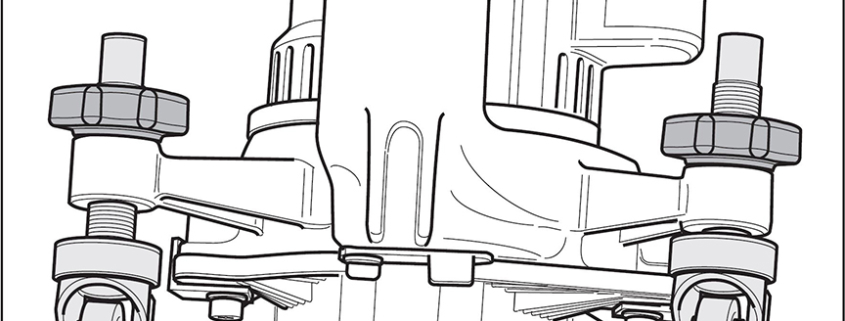

For rougher or finer sanding with the FLIP, you only need to take a quick minute to adjust the angle of the machine, using the two wheel posts (See “Adjusting

the Guide Rollers” section in the operation manual). You do that with the universal spanner, the T-shaped screwdriver that accompanies a purchase of

a new FLIP.

The black spanner handle is marked with “short” on one end and “long” on the other. Short and long refer to the short and long FLIP attachments. Use the

appropriate end of the spanner handle to apply the standard wheel setting for whichever FLIP attachment you are using. For the corner attachment, use

the short spanner.

It’s important to use the same setting for both wheels. Otherwise, the FLIP will sit unevenly on the floor, and it will cut unevenly.

How to Set the Standard FLIP Wheel Position

With the FLIP turned off and unplugged, follow these easy steps to make sure you are sanding evenly and with the least amount of physical effort:

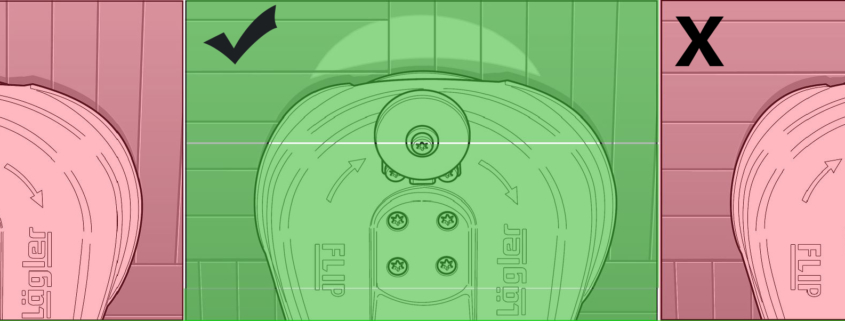

If your settings are even, the sanding area will appear centered in front of the FLIP. Uneven guide roller settings will produce sanding that is off-center

to the left or right, to whichever wheel is set lower.

Adjusting for Fine vs. Rough Sanding

For finer sanding with the FLIP, close the gap between the wheel and the fan housing arm. To increase aggressiveness, increase the space between the wheel

and the fan housing arm.

Another way to look at it is that the higher the locknut is set when tightened, the rougher the FLIP is set to cut. The lower the locknut is set when tightened,

the finer the FLIP is set to sand.

Learn more about using the Lägler FLIP and other Lägler sanding machines.

Become Lägler certified through our Premium Sanding Technology (PST®) training.

Related FLIP Parts

Guide Roller: LNA# P626 | Mfr# 100.45.01.105

Universal Spanner: P1230 | 000.91.40.001

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.