You are here:

The last thing you want with a floor you’ve sanded and finished is to have sanding marks pop like neon signs in the night. If you can spot sanding marks

while standing at full height on the floor and looking only with ambient light, then something went wrong.

This final blog post that comes from Lägler’s “Sanding of Wooden Floors” manual (free download) lays out the reminders of how to avoid sanding marks ruining

your success on the job.

The wood flooring and expansion gaps or the staircases always should be thoroughly vacuumed immediately before each work step (every sanding step, gap

filling or surface treatment).

Here are some general tips to keep in mind:

The finish coat was accidentally sanded through at certain spots during the intermediate finishing sanding, which later leads to differences in the brightness

on the completed finished surface.

An abrasive with a different grit and cutting material was used for the edge sanding as for the previous field sanding.

Glossy spots can be seen on the surface (cloud formation). The same abrasive was used for too long in the last sanding step that it became too blunt. Excessively

blunt abrasives burnish the wood surface.

The wood absorbs less finish on burnished spots. This causes differences in the brightness.

The abrasive must be changed frequently enough to prevent burnished spots.

The final sanding step was performed with an excessively coarse grit. Oiling requires finer sanding than finishing.

For the full rundown of how to get the most out of your sanding machines, especially if they are Lägler machines, read each post on this blog.

Or, better yet, download Lägler’s free PDF, print it out, carry it on your phone,

whatever will help you and your crew be the best you can be.

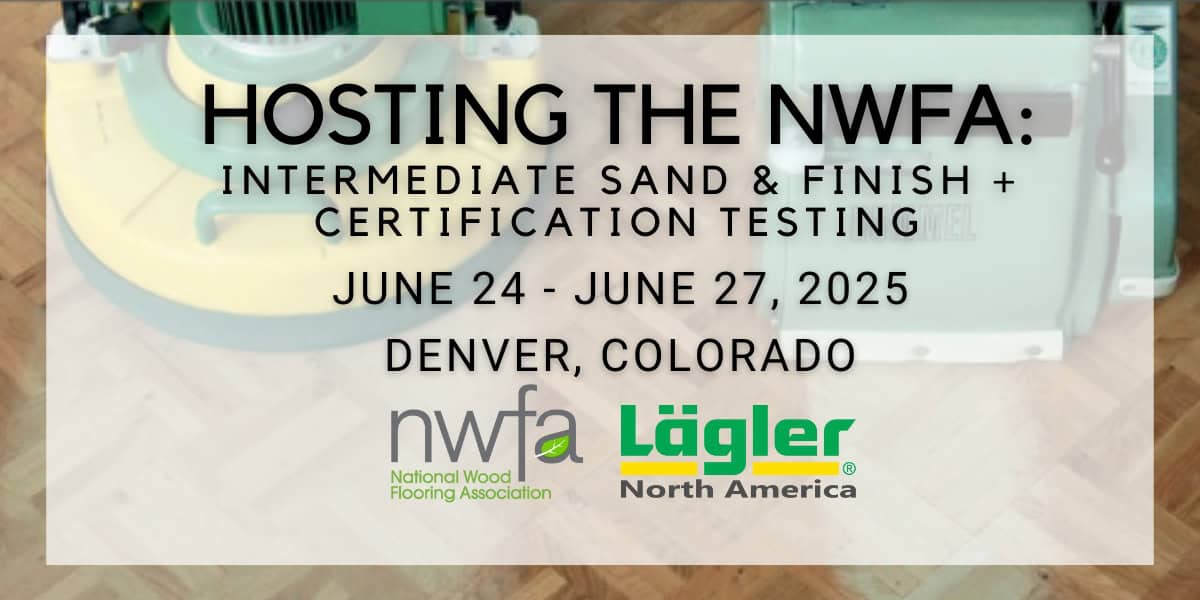

Hands-on training and instruction are available through Lägler’s one-day Premium Sanding Technology (PST®) certification course, too. Call 800-848-6635 to schedule your session in Denver.

How to Minimize Sanding Efforts + Maximize Business Profits

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.