You are here:

Sanding wood floors is a science. Knowing that science is what sets you apart from DIY homeowners who want to save a buck and try their luck.

In fact, when a lifestyle blogger reached out to us a few days ago wanting some tips for an article on “refurbishing” wood floors, this was our answer:

Hire a professional. Then we laid out some truth on what it takes to be good at sanding floors, how someone who is inexperienced is virtually certain

to jack up his/her floors. Hire. A. Professional.

That said, even pros aren’t gifted at birth with knowing the science it takes to perfect a floor. Learning is a process that never ends.

For example …

1. We see photos on Instagram everyday showing people running big machines. Some are moving left to right across the room. Some are moving right to left.

Some run parallel to the straight-laid boards, and others cut at a slight angle across them.

Do you know … What’s the best way to sand a wood floor: moving from left or right, and parallel or at an angle? What might be exceptions to the rules?

2.Your big machine has variable pressure settings. For the Lägler HUMMEL, there are three – coarse, middle and fine – that can be chosen by use of a simple

lever. Other big machine models have their own adjustment mechanisms.

Do you know … Which big machine pressure setting should you use for what situation, and when?

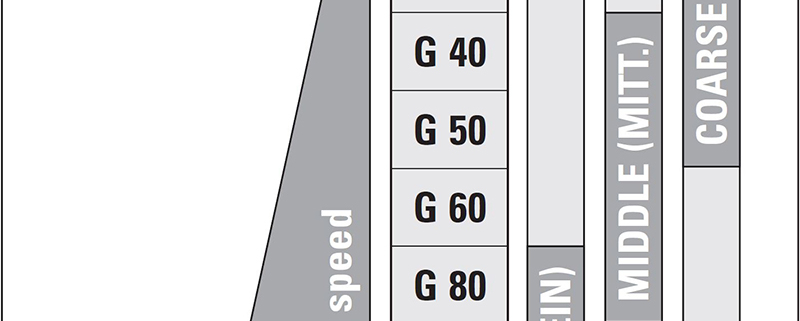

3.Then there’s speed. How slow or fast you walk when using the big machine relates to the pressure setting and abrasive grit you’re using. How hard or

soft the species of wood you’re sanding has an impact, too.

Do you know … How fast (or slow) should you dance with your big machine? And what speed with what grit abrasives?

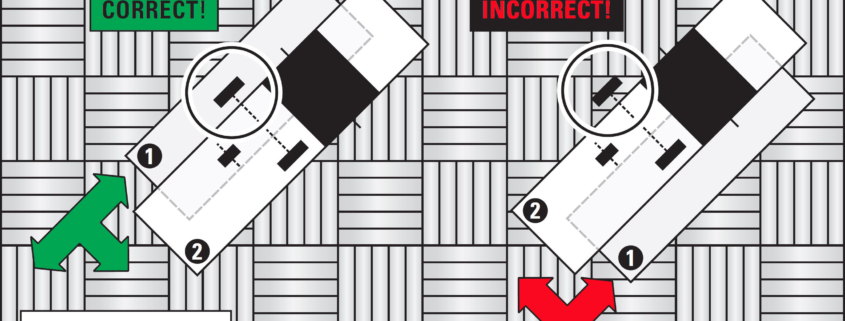

The HUMMEL’s eight-inch sanding drum is positioned at the right edge of the machine. The lateral wheel that trails the drum always rolls on the freshly

sanded surface.

Because the drum is on the right side of the HUMMEL, the left wheel runs on whatever surface – sanded or not yet sanded – the left side of the HUMMEL passes

over. Forward and backward.

By sanding left to right across the field of the room, all wheels of the HUMMEL will run on the same sanded surface. The machine will be level and you’ll

get optimal flatness as a result, avoiding waves. This benefit carries out in a domino effect for each sanding step in the process.

The exception to the rule is in tight or awkward spaces where common sense tells you to throw a change-up.

If you sand with the direction of straight-laid floor boards, you are maintaining what has happened to that floor over time. You’re giving it a new look,

no doubt. But the flatness …

When you sand at an angle, you are:

Until recently, Lägler recommended in its sanding manual to sand at an angle except for the final pass.

When sanding at an angle, at first, the scratch pattern will be more noticeable than when you cut with the direction of the floor boards. But as you sand

with increasingly finer grits and, especially, if you use a quality multi-disc sander in the process, you will remove those scratches.

Lägler now recommends to sand at an angle for all passes with the big machine.

The exception to this rule is when dealing with cupped boards of a straight-laid floor. On the first run across the floor, knock those

edges down with a head-on attack. Then go to sanding at a slight angle.

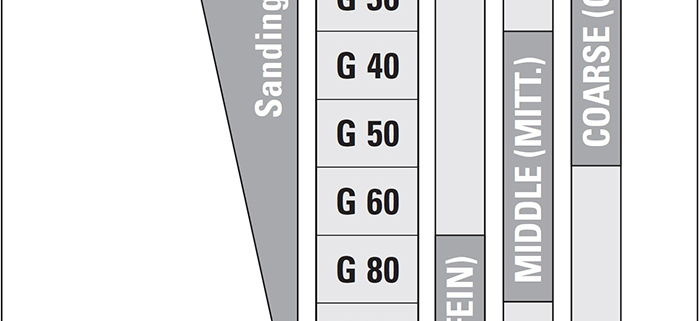

Sanding pressures with the big machine are tied to abrasive grits. The finer the grit, the less drum pressure you should use.

The wood species matters, too. Softer woods should be sanded with less pressure, so not to cut too deeply into the floor.

The chart above, from Lägler’s “Sanding of Wooden Floors” manual, lays out grits related to pressure settings. Clear cut. Common sense.

When you have an extra-rough floor or one that’s damaged or coated with a hundred years of nasty, get mean with that first run. If you’re using 16 grit,

you know it makes sense to put on the coarse drum pressure to make the most of it.

To minimize sanding marks and save time in the process, pace yourself. Not too fast, not too slow. No matter how many years you have at the lever, this

relationship has to move at a steady pace. Keep in mind the grit and drum pressure. Overall, consistency is king.

For softer species, a little quicker walking speed will keep you from cutting too deeply into the floor. Or maybe it’s just that you need a slower speed

for harder species. You’re the pro on the job. If you’re getting worse scratches than you want, change the music you’re groovin’ to and adjust your

dance moves.

Learn more about the fine details of floor sanding craftsmanship. Participate in Lägler’s one-day Premium Sanding Technology (PST®) certification course.

And download the Lägler “Sanding of Wooden Floors” manual online. It’s free.

How to Minimize Sanding Efforts + Maximize Business Profits

How to Subfloor Prep with a Multi-Disc Sander or Buffer

Big Machine Sanding Path Displacement

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.