You are here:

Have you noticed the six arrows on the bottom of a Lägler TRIO sanding disc? We point them out during our Premium Sanding Technology training (PST® certification). A lot of times, the guys hadn’t noticed

The Lägler HUMMEL weighs about 175 pounds. That weight is important for sanding wood floors with the HUMMEL, but it’s no doubt tough on your back when carrying the machine for long. Any of you

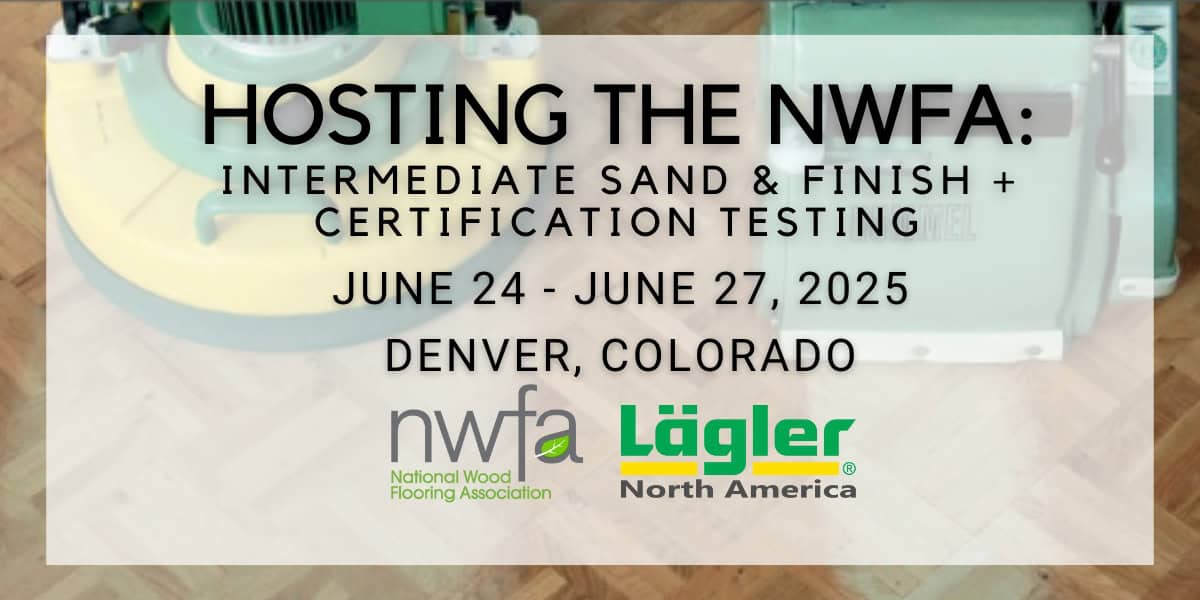

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.