Have you ever compared a decades-old Lägler HUMMEL and a new one, and wondered what’s changed? We get it. At first glance, they look a lot alike. Two things:

1. Don’t change what ain’t broken …

2. … unless you can make it even better.

For Lägler, better happens in micro-innovations, the little refinements that become possible with new technologies and materials. And, improvements happen

with feedback from all you pros using the machines on floors around the world.

Why does Lägler micro-innovate instead of putting out a whole new belt sander beast every so many years? Stop us if you’ve heard this one. The answer is

consistency, for Lägler and for you. (We’ve mentioned consistent quality many times on this blog and social media as a key to success.)

We assume you would like to keep your big machine running, and not feel like you have to replace it to stay on top of your game.

If you have a HUMMEL (and maintain it properly), or if you talk with someone who does, how many HUMMELs have they had to replace over the years?

A better question is: How many decades have they used their HUMMEL, grinding floors on a daily basis, and not had to replace it?

Like we say, “You buy a new HUMMEL because your business is growing up, not because it’s breaking down.”

Lägler assures compatibility of new parts with existing machines. All new parts work with older models. That’s why the overall look of

Lägler machines has been consistent, despite all the technical refinements every key part of it has received along the way.

Micro-innovations enable you to never be cut off from the parts you need to keep your machine running just like you need

it, for as long as you need it.

A few examples of Lägler micro-innovations are below.

Micro-innovations mean new-and-improved parts function on older machine models, like the new lateral wheels shown above with a 1983 HUMMEL.

The original lateral wheel design for the HUMMEL had a sheet-metal side wall. The old wheels had considerably more components, too.

The synthetic wheel facing was grouted onto the wheel hub, making it difficult to change out the wheel.

Today’s lateral wheel (P147/P149W),

which is made of lower-wear material is more durable and less likely to leave wheel marks on the floor. It also can be replaced easily without needing

to disassemble the whole wheel unit.

Why this helps you? One step is all it takes now to take off a worn lateral wheel and be able to replace it with a new one: Remove the

one screw and washer set.

Bonus Tip: Lägler recommends cleaning your wheels before every sanding job, and to consider keeping an older set of wheels to put on the

HUMMEL for first passes on tough finish removal. Swap out the wheels again in less than a minute, and you’re set for smooth final cuts.

The Lägler HUMMEL upper roller unit is one example of micro-innovation at the company. The current version is on the left.

The upper roller unit originally

was steel. Since 1990, it’s been aluminum.

This material change makes production easier. It takes welding out of the process. The aluminum body of the unit can be made in one cast.

Why this helps you? The aluminum upper roller enables more precise belt control and better tracking adjustment.

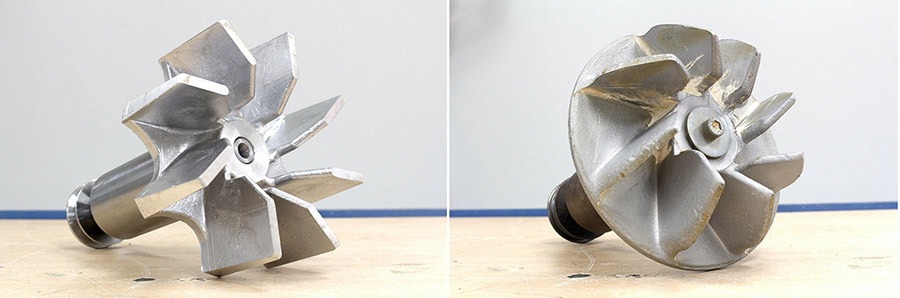

The Lägler HUMMEL fan insert has been refined over the years. For example, on the early 1990s fan in the photo above (right), the space between the blades

is solid aluminum. The current model (left) benefits from a micro-innovation designed to remove some of that material.

In the beginning, the fan blades were mounted with tongue-and-groove joints. Now, fans are cast as one piece.

The blades originally were symmetrical. They were reworked in 1990, increasing airflow by using an asymmetrical blade design. The cavity between the blades

was increased during a 1997 design upgrade. (P169, Fan Insert Complete)

How these micro-innovations help you? The lifespan of the fan blades increased significantly. Production processes became easier. Overall

quality got better.

Got a 50-year-old HUMMEL? No problem. Older HUMMEL sanders can be upgraded with the current versions of all parts. Your HUMMEL, no matter its age, will

not be obsolete.

Save money. Don’t replace the sander. Just maintain, replace parts, as needed, and grind on. Then, pass your Lägler down to the next generation when you

retire.

6 Things You Need to Know About Sanding Drums

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.