You are here:

By Karl Lägler A goal for every contractor’s business should be to minimize effort and time on-site while maximizing quality results and profits. Wood floor sanding is hard work, but that doesn’t mean it can’t

Have you heard of “hidden champions”? We recently heard this tag, what it means, and who it’s talking about. And started thinking about all the amazing champions in wood flooring. Pros who knock out beautiful

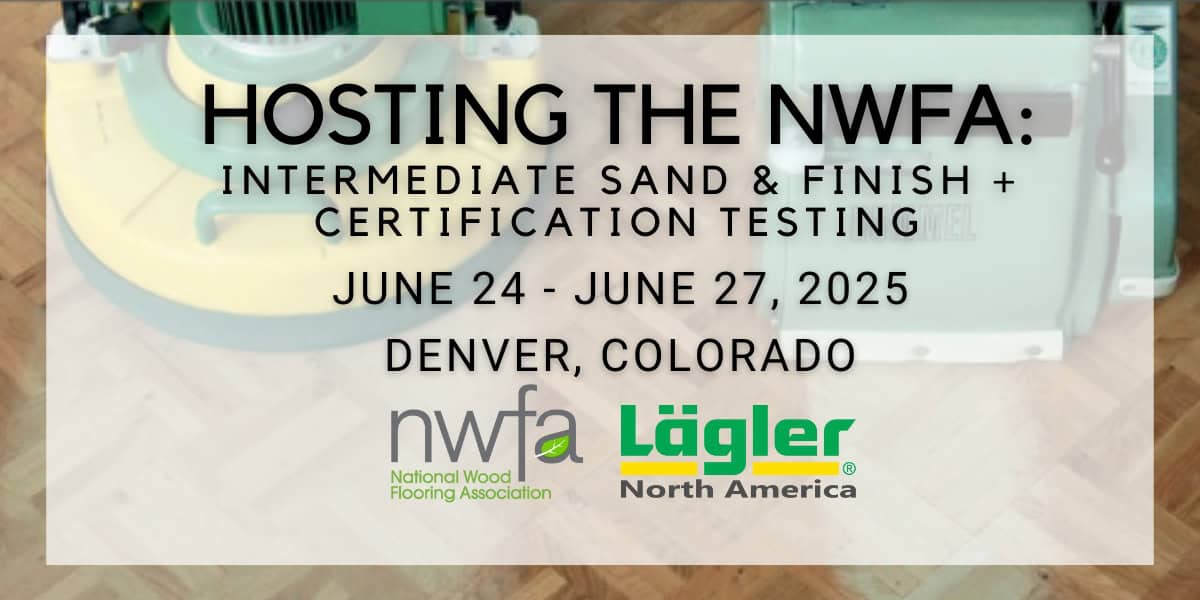

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.